Commercial aviation alone contributes around three percent of total global carbon emissions. But the industry is actively looking for green solutions in the form of sustainable jet fuel, and in one case, that fuel may have had a previous life as your household food scraps. In one study in the Proceedings of the National Academy of Sciences, a team of researchers from the National Renewable Energy Laboratory in Golden, Colorado and other institutions details a method of converting food waste into sustainable jet fuel that can be used in existing engines.

Biomass, such as manure and food waste, can be converted into biofuels, which are renewable liquid fuels made from organic matter. Ethanol and biodiesel are two common types of renewable biofuel, but making sustainable aviation fuel is a more complicated process—it’s got to be so similar to the petroleum-based jet fuel we use today so it can “drop-in” existing engines and aircraft. Reimagining the airplane engine to run on different types of fuel will take time, so the goal is to design a fuel that can be used now. The researchers were able to use volatile fatty acids from fermenting old food waste and convert it to simple paraffin molecules that can be used in fuel and really aren’t all that different chemically from traditional fossil fuels. Other sustainable aviation fuels have been made from biomass, specifically oil, fat, and grease from vegetables and animals, but using our ever-mounting pile of food waste to fuel flight broadens those possibilities.

Annually, over 21 billion gallons of jet fuel are consumed in the United States alone. This number is expected to double by 2050 as observed by the U.S. National Renewable Energy Laboratory (NREL). In relation to this newfound concern, a target for carbon footprint regulation is proposed for jet fuel production in conjunction with the United Nations Net Zero Coalition.

What is net zero? As described by the United Nations, “Net zero means cutting greenhouse gas emissions to as close to zero as possible, with any remaining emissions re-absorbed from the atmosphere.” For jet fuel, the target is set to at least a 50% reduction by 2050 and is intended to be achieved through Sustainable Aviation Fuel, commonly called SAF.

Engine challenge

SAF is any kind of biofuel used to power aircraft which have similar properties to conventional fuel but with a much much lower carbon footprint. SAF development had been in going progress for a while without generating any promising result. Any new type of fuel being proposed didn’t seem to be compatible with the current aviation engine. That is until the emergence of SAF from wet waste as proposed by a team of researchers from NREL and other institutions.

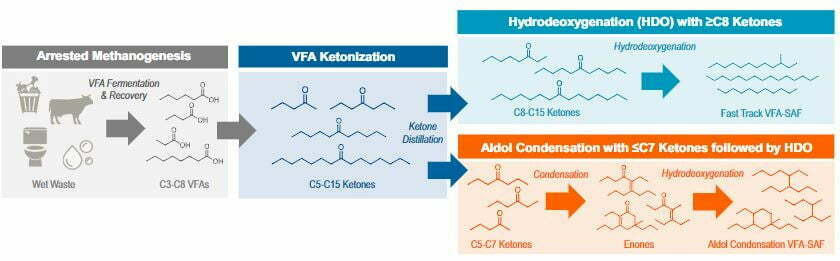

The SAF is processed from wet waste such as food waste, feedstock waste, animal manure, and wastewater sludge, essentially any kind of daily waste that contain a high level of water content. The wet waste then turned into volatile fatty acids (VFA). With the addition of catalyst and carbon to VFA molecules, scientists managed to turn the VFA into a long chain of energy-rich paraffin hydrocarbons, chemically similar and serving the same purpose as that of conventional jet fuel.

This new-found method of SAF from wet waste has the energy potential to displace over 20% of US jet fuel consumption per year. Not only that, but the utilization of wet waste also decreases the amount of food waste stacking up the landfill. This act helps reduce the release of greenhouse gas discharge, the deadly emissions causing climate issues. The implementation of wet waste SAF production is projected to achieve a 65% drop in carbon emissions compared to conventional fossil fuel production.

Killing two birds with one stone

This new approach can kill two birds with one stone – creating low carbon footprint jet fuel and reducing greenhouse gas emissions. And in addition, we will also effectively use our food waste.

With the state-of-the-art of SAF development, researchers are still trying to find the best way of making this method accessible for scale-up projects. The complexity of the process and the high moisture of the raw material makes it difficult to suddenly implement it on a bigger scale. Going forward, researchers are eager and diligent to serve the complete production of this wet waste-derived SAF to a wider audience, and we might not have to wait that long for it to happen!

According to NREL scientist Derek Vardon, after the process has been solidified and passed the ASTM International’s fuel property requirements, it can take one to two years for prominent airlines to get the fuel regulatory approvals and start using wet waste SAF for commercial flights. “That means net-zero-carbon flights are on the horizon earlier than some might have thought.”

Questions and Answers

Andreea Moyes, Air bp’s global aviation sustainability director, gives the low down on sustainable aviation fuel. Interview available at https://www.bp.com.

The use of sustainable aviation fuel (SAF) is on the rise, but what is it exactly?

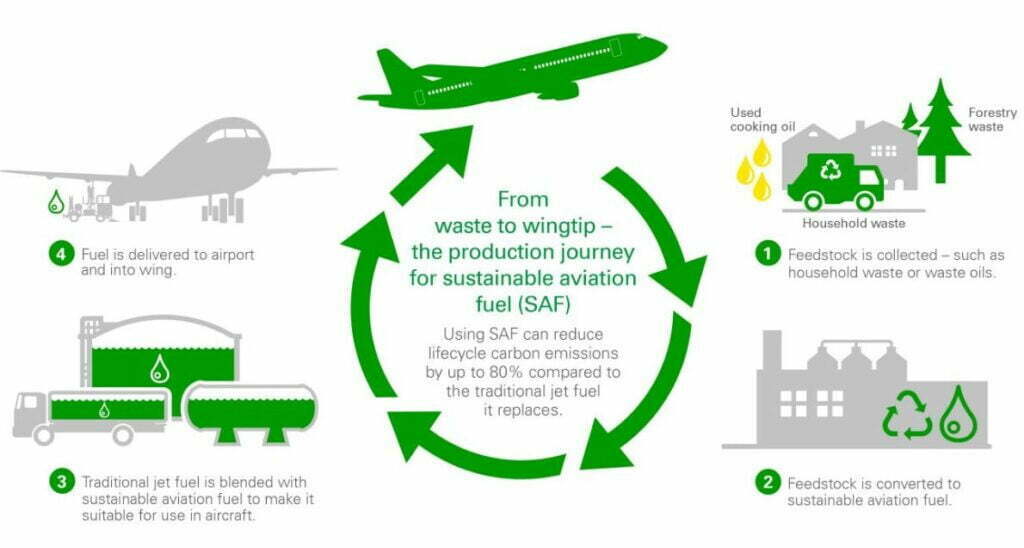

SAF stands for sustainable aviation fuel. It’s produced from sustainable feedstocks and is very similar in its chemistry to traditional fossil jet fuel. Using SAF results in a reduction in carbon emissions compared to the traditional jet fuel it replaces over the lifecycle of the fuel. Some typical feedstocks used are cooking oil and other non-palm waste oils from animals or plants; solid waste from homes and businesses, such as packaging, paper, textiles, and food scraps that would otherwise go to landfill or incineration. Other potential sources include forestry waste, such as waste wood, and energy crops, including fast growing plants and algae. Air bp’s SAF is currently made from used cooking oil and animal waste fat.

Why is SAF important?

Jet fuel packs a lot of energy for its weight and it is this energy density that has really enabled commercial flight. Today, there aren’t any other viable options for transporting groups of people quickly over very long distances, so we’re dependent on this type of fuel in aviation. A return flight between London and San Francisco has a carbon footprint per economy ticket of nearly 1 tonne of CO2e. With the aviation industry expected to double to over 8 billion passengers by 2050, it is essential that we act to reduce aviation’s carbon emissions and SAF is one way in which Air bp is doing that.

How much carbon does it save?

SAF gives an impressive reduction of up to 80% in carbon emissions over the lifecycle of the fuel compared to traditional jet fuel it replaces, depending on the sustainable feedstock used, production method and the supply chain to the airport.

What are Air bp’s sources of SAF?

When it comes to sourcing SAF Air bp has a portfolio approach. We agree off-take agreements with third-party producers and this security of demand can help these third parties secure investment. Secondly, we invest in third-party production facilities. Air bp’s collaboration with California-based Fulcrum is one example. Air bp entered into a strategic partnership with Fulcrum BioEnergy in 2016 and Fulcrum is building its first plant in Reno, Nevada, which will produce sustainable transport fuel made from household waste. Fulcrum intends to construct additional facilities and will supply Air bp with SAF from several different plants. Thirdly, bp is investing in its own refineries and facilities. One such example is the sale of ISCC plus SAF Air bp announced in July at bp’s Castellon refinery in Spain; and in October 2021 the refinery became the first globally to achieve the ISCC CORSIA certification.

Is it safe to use?

SAF can be blended at up to 50% with traditional jet fuel and all quality tests are completed as per a traditional jet fuel. The blend is then re-certified as Jet A or Jet A-1. It can be handled in the same way as a traditional jet fuel, so no changes are required in the fuelling infrastructure or for an aircraft wanting to use SAF. In 2016, we were the first operator to commence commercial supply of SAF through an existing hydrant fuelling system, at Norway’s Oslo Airport.

Is SAF suitable for all aircraft?

Any aircraft certified for using the current specification of jet fuel can use SAF.

Who has Air bp supplied?

To date, Air bp has supplied SAF at over 20 locations across three continents. Air bp’s SAF has been used to fuel many different types of aircraft from small private jets to large passenger aircraft. We have a supply chain established in Sweden, from which we are supplying locations across the region. It was this supply chain that enabled us to fuel Braathens Regional Airlines for its ‘Perfect Flight’ back in May 2019, which combined the latest in aircraft efficiency and the use of SAF to cut lifecycle emissions compared to regular flights on the same route.

How does the cost of SAF compare to traditional jet fuel?

SAF is currently more costly than traditional fossil jet fuel. That’s down to a combination of the current availability of sustainable feedstocks and the continuing development of new production technologies. As the technology matures it will become more efficient and so the expectation is that it will become less costly for customers. We are seeing increased uptake of SAF as our customers and their passengers increasingly recognize and value the benefits of the emission reductions.

Is SAF really the key to making aviation greener?

SAF can drop straight into existing infrastructure and aircraft. It has the potential to provide a lifecycle carbon reduction of up to 80% compared to the traditional jet fuel it replaces. SAF will play a really important role in meeting the aviation industry’s carbon reduction targets, however, we need to use all the options to reduce carbon that we have available. There are several broad opportunities for carbon reduction across the industry such as more efficient aircraft design, smarter operations and the development of future technologies like electrification. In that regard, in 2016 Air bp became the first aviation fuel supplier to be independently certified carbon neutral for into-plane fuelling operations at all its global operated locations.

So why aren’t more airlines using SAF?

At the moment, production of SAF is limited as the higher cost for SAF is preventing wider uptake. Air bp is working on helping create more demand in the short-term which will lead to more production and hopefully lower costs in future.

How can we accelerate the growth of SAF?

There is real commitment from the industry to reduce carbon emissions, but governments also need to create the right policies to accelerate the growth of SAF. Increasing production requires long-term policy certainty to reduce investment risks, as well as a focus on the research, development and commercialization of improved production technologies and innovative sustainable feedstocks.

On an individual level, some airlines are now providing passengers and corporate customers with the option to fund the use of SAF in order to reduce emissions associated with your ticket, and we think these are really positive initiatives.

The key to greater acceptance and deployment of SAF is reduction in costs. Over the long term, that will require investment in advanced technologies to process feedstocks more efficiently at greater scale and investment in the development of sustainable and scalable feedstock options. However, in the short-term, interim support from governments and other stakeholders through policy incentives is needed. This support needs to be part of a long-term framework to give investors the confidence to make the big investments required to grow supply.

This article was created as part of the TeaMWork program that brings together students across the globe (Monash University in Australia and Malaysia, and the University of Warwick in the United Kingdom).

Author: Beatrix Theodor Valentia, Monash University Australia